Parts with passports: GM’s NAFTA road to production

24

0

BROADCAST AND DIGITAL RESTRICTIONS~**

Broadcasters: NONE Digital: NONE~**

Before this engine even goes under the hood of a General Motors automobile - the sum of its parts have already racked up some serious miles, and not all of them within America's borders.

Powdered steel from Tennessee is shipped to Pennsylvania and used to form connecting rods for pistons. Those piston rods are then sent across the northern border to Canada where bolts and other vital components are added on. But the manufacturing isn't done yet and neither is the journey for these parts. Next, they're sent all the way down from Ontario, Canada to Mexico where rings and seals are added. The final step: completed rods are individually wrapped and carefully loaded onto trucks for a road trip back to the U.S. to this GM engine plant in Romulus, Michigan.

The parts combined have crossed borders four times without getting hit with any tariffs.

This is the world of manufacturing supply chains: where factory operators like GM pull together raw materials, parts, and labor from wherever they can get it the cheapest to keep total production costs down.

Jim Bovenzi is executive director of the global supply chain for General Motors.

SOUNDBITE: JIM BOVENZI, EXECUTIVE DIRECTOR OF GLOBAL SUPPLY CHAIN, GENERAL MOTORS:

"Right now there are pockets of expertise that exists in certain locations and if those borders were to close or to change, even availability could be an issue for a company the size of General Motors, as well as competitiveness, again, certain products are best produced in certain areas and having access to a larger region gives us a greater deal of competitiveness."

In GM's case - and for Detroit's other members of the big three - Ford and Fiat Chrysler - free-trade between Mexico, the U.S. and Canada can only happen profitability because of the North American Free Trade Agreement. But President Trump has threatened to rip up the 25-year-old pact if he doesn't get his version through Congress.

His replacement - the United States Canada and Mexico Agreement, or USMCA - is designed to force U.S. automakers to build more vehicles and components like these in the U.S., using higher-paid American labor. Automakers worry that will push up labor costs and ultimately the final sticker price.

But that worry is nothing compared to what would happen if there's no trade agreement at all.

Take the 400,000 V6 engines pumped out of this GM assembly floor a year - of major suppliers: 67 are from the U.S., 13 from Mexico, 8 are from Canada and 12 from shores even farther away, with most of the electronics coming from Asia.

Any trade disputes or hold-ups at the border are a headache.

SOUNDBITE: JIM BOVENZI, EXECUTIVE DIRECTOR OF GLOBAL SUPPLY CHAIN, GENERAL MOTORS:

"We run a lean supply chain. Typically a plant will have less than a day's worth of a material in their four walls as a buffer and so a disruption or a delay at a border can wreak havoc in a supply chain."

And GM can't afford that. Now fully assembled, these engines take an 8-hour drive south from Michigan to Tennessee….where - hopefully waiting for them - are more than 5200 parts including more from NAFTA partners Mexico and Canada - which all go into making the Cadillac or GMC SUVS headed for U.S. roadways.

相關影片推薦

1:51

凌晨2點32分花蓮大地震全台驚醒 規模6.3富凱飯店倒了民視影音168,979 次觀看・8 小時前1:30

嗆中駐美大使「雙手沾血」! 哈佛學生遭起底是台灣人|#鏡新聞鏡新聞98,097 次觀看・18 小時前1:39

"亮警證"幫女友家人喬車位 內湖分局將懲處員警民視影音261,431 次觀看・1 天前1:50

花蓮港震後潮差大! 港口水位「剩不到3米」船恐觸礁華視影音40,514 次觀看・18 小時前 1:41廣東「百年一遇」暴雨強襲 橋梁瞬間崩塌 空拍看水鄉澤國、土石流覆蓋山坡Yahoo奇摩(國際通)80,999 次觀看・21 小時前

1:41廣東「百年一遇」暴雨強襲 橋梁瞬間崩塌 空拍看水鄉澤國、土石流覆蓋山坡Yahoo奇摩(國際通)80,999 次觀看・21 小時前1:25

掛身障車牌停"專用車位"遭罰!民眾氣炸申訴 警坦承疏失撤單民視影音2,337 次觀看・20 小時前1:55

徐巧芯指早餐店日賺2萬 四叉貓質疑沒開發票民視影音8,134 次觀看・8 小時前3:31

追不到砍她176刀致命 王鴻偉拖15年未槍決華視影音328,159 次觀看・2 天前1:44

凌晨規模6連2震!花蓮統帥大樓「軟腳傾倒」 住戶親曝人員現況民視影音2,980 次觀看・10 小時前 4:09一分鐘報天氣 / 週二 (04/23) 鋒面南下至臺灣 未來一週天氣不穩定留意局部大雨Yahoo奇摩新聞(報氣象)10,322 次觀看・20 小時前

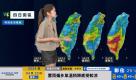

4:09一分鐘報天氣 / 週二 (04/23) 鋒面南下至臺灣 未來一週天氣不穩定留意局部大雨Yahoo奇摩新聞(報氣象)10,322 次觀看・20 小時前

熱門必看

14:01

邱宇辰、黃宏軒演出腐女心中的幻想!超禁忌兄弟戀讓唐老師興奮到模糊!?Ep.215-1唐綺陽談星室31,703 次觀看・1 天前24:07

【小瑜星座】高段位愛情專家 令人震撼的雙魚女雷達之星3,141 次觀看・3 天前19:54

跑步一定又喘又累?不會累的 #超慢跑,該怎麼跑才能控糖、減脂?ft. 超慢跑教練 徐棟英老師 @tongyinghsu 《 強者我朋友 》|志祺七七志祺七七 X 圖文不符2,147 次觀看・2 天前26:20

【東京近郊景點】栃木那須高原✨距離東京1小時!絕景森林步道、生起司蛋糕CHESSE GARDEN、沼原濕原、那須彩繪玻璃美術館、那須溫泉神社、殺生石、那須動物王國|東京自由行・Japan 4Kvlog吉田社長交朋友1,252 次觀看・1 天前1:08

周慧敏 倪震夫婦罕同框 舉止親密力破婚變傳聞娛樂星聞16,482 次觀看・3 天前

Yahoo TV

Yahoo TV